Sheet Piling Retaining Walls stop soil erosion and keep the ground stable. They use prefabricated sheet materials driven into the ground. This makes them great for keeping storm damage away from marine areas.

These walls help keep land safe from erosion. This keeps properties safe and valuable. Sheet piling is a key part of construction, helping control erosion costs.

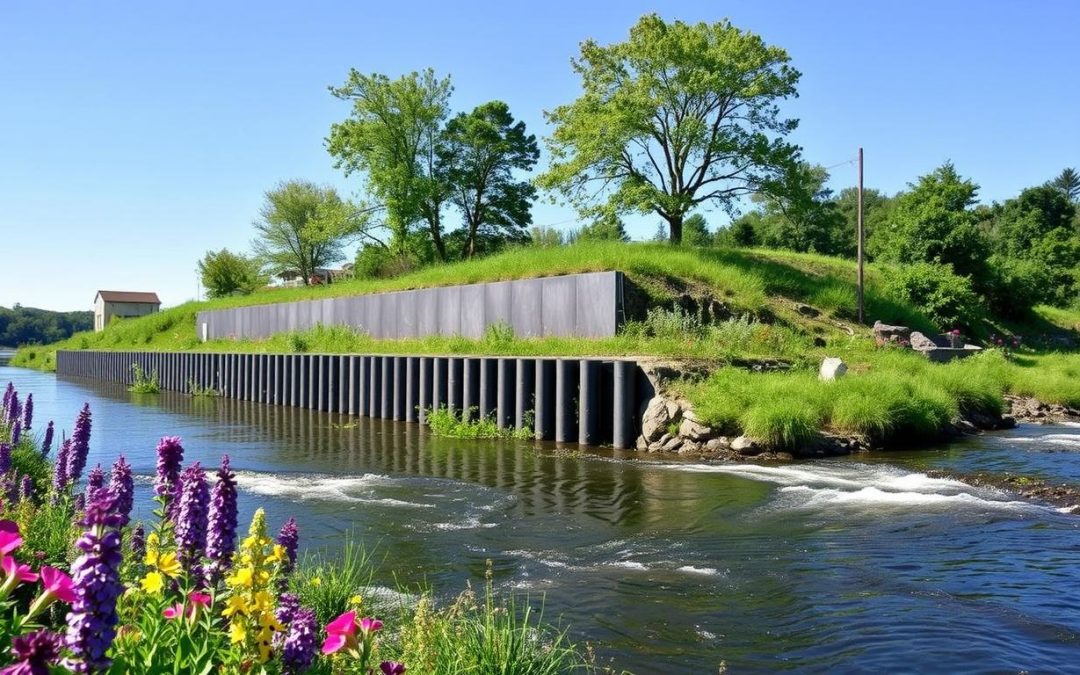

Steel sheet piling is used to protect coastlines, like in Blankenberge, Belgium. It shows how well sheet piling works in the sea. Projects like these show its power in stopping erosion.

Retaining Wall Systems, like sheet piling, are key for stopping erosion. They are very important and work well.

Key Takeaways

- Sheet Piling Retaining Walls are a reliable solution for erosion control and storm protection in marine environments.

- Retaining Wall Systems, including sheet piling, offer a cost-effective solution for construction projects.

- Sheet piling involves driving prefabricated sections of sheet materials into the ground to form a continuous barrier.

- Steel sheet piling installation has been used as a robust storm protection measure for coastal areas.

- Regular maintenance and inspection of sheet piling are essential to ensure long-term effectiveness.

- Sheet pile retaining walls are known to be cost-effective compared to other types of retaining walls.

What are Sheet Piling Retaining Walls?

Sheet piling retaining walls are made from steel sheets. They are driven into the ground to form a strong wall. These walls keep soil and materials in place, stopping them from sliding or falling.

The Steel Sheet Piles used in these walls are very strong. They can hold a lot of weight, making them great for many projects.

The design of the Sheet Pile is very important. It depends on the soil, wall height, and expected weight. You can use timber, concrete, or steel for sheet piling, each with its own benefits and drawbacks.

Steel Sheet Piles last a long time and are very strong. They don’t rust easily and are easy to put up. They work well for marine walls and other types of walls. The design can be changed for each project, making sure the wall is safe and works well.

Benefits of Sheet Piling Retaining Walls

Sheet piling retaining walls are very durable and cost-effective. Geotechnical engineering helps design and build these walls. They can handle many environmental challenges.

These walls are great for stopping erosion and keeping soil in place.

Some big benefits of sheet piling retaining walls are:

- They can handle a lot of soil and water pressure.

- They go up fast, unlike concrete walls.

- They come in many shapes and sizes for different needs.

Steel sheet piles are very flexible and easy to put up. They also need less trucking and can be recycled. Working with geotechnical engineers and piling contractors helps pick the best sheet pile for a project. This makes sure the structure is strong and lasts a long time.

Types of Sheet Piling

Sheet piling is a key method in earth retention systems. It works well based on the material used. Knowing about soil mechanics helps pick the right sheet piling for a project.

There are many types of sheet piling. Each has its own good points and not-so-good points.

Steel Sheet Piles

Steel sheet piles are very common. They stand up well to high forces and keep water out. They work with all soil types and don’t need digging for foundations.

Steel sheet piles are also good for the environment. They can be taken out easily and cut down on waste.

Vinyl and Plastic Sheet Piles

Vinyl and plastic sheet piles are cheaper for controlling soil erosion. They are light, easy to put in, and don’t rust. They’re great for short-term projects like walls and bulkheads.

Composite Piling Options

Composite piling mixes materials like steel and concrete. These systems are very strong and last a long time. They’re perfect for deep holes and keeping earth in place.

Sheet piling is very important in earth retention systems. It stops soil from washing away and keeps structures stable. By knowing about the different sheet piling types, engineers and builders can choose the best one. They consider soil mechanics and the environment too.

Applications of Sheet Piling Retaining Walls

Sheet Piling Retaining Walls are used in many places. They help with waterfront projects, building sites, and keeping water out. Steel Sheet Piles make these walls strong and last a long time.

Waterfront Applications

Steel Sheet Piles stop soil from washing away at the water’s edge. This is key in coastal areas where waves and tides can erode the soil.

Site Support for Construction Projects

These walls also support construction sites. They can be a temporary or permanent base for buildings. Using Steel Sheet Piles can make building faster and cheaper.

Flood Protection Solutions

Sheet Piling Retaining Walls keep water out in flood-prone areas. They protect buildings from water damage. Steel Sheet Piles make a strong barrier against floods.

Installation Process for Sheet Piling

Installing sheet piling is a detailed task. It needs careful planning and execution. It includes site assessment, driving piles, and backfilling. Retaining Wall Systems are key for support and stability. The Sheet Pile Design is also important, as it decides the sheet piling type and size.

First, a site assessment is done to check soil and obstacles. This info helps make a specific plan for the site. Then, the sheet piling is driven into the ground. This is done with a vibratory or impact hammer, based on the soil.

- Using guide structures or templates to ensure correct alignment

- Driving the piles carefully to avoid damaging the surrounding soil

- Backfilling the trenches with soil or other materials to provide additional support

By following these steps, sheet piling can be safely and effectively installed. Using Retaining Wall Systems and good Sheet Pile Design ensures success. This makes sure the sheet piling supports the project well.

Maintenance of Sheet Piling Retaining Walls

Keeping sheet piling retaining walls in good shape is very important. Geotechnical Engineering helps a lot in keeping these walls strong. The first thing to do is check them often.

This helps find any damage or wear early. Look for signs like corrosion, bends, or leaks. These can make the wall weak.

Spotting damage early is key to avoid big problems. To check the walls, people use eyes, drones, special tests, and more.

Fixing damaged walls is also important. This can be done by welding, adding concrete, or using special coatings. How well these fixes work depends on the materials used. Regular checks and fixes can make these walls last longer and work better.

Comparing Sheet Piling with Other Retaining Wall Solutions

Sheet piling is just one way to hold back soil. Knowing about soil mechanics helps pick the right wall for a project. We’ll look at sheet piling, concrete walls, gabion walls, and timber walls.

Concrete Retaining Walls

Concrete walls are strong and last long. They’re good for deep holes and heavy loads. But, they cost a lot and need a lot of prep work.

Gabion Walls

Gabion walls are eco-friendly. They’re made from wire baskets filled with rocks or soil. They look natural and are used in landscaping and to stop erosion.

Timber Retaining Walls

Timber walls are cheaper for small jobs. They’re simple to put up and use green materials. But, they’re not for heavy loads or deep holes.

Choosing a wall depends on the project’s needs. This includes the soil, how deep, and how much it can hold. Knowing about soil and walls helps pick the best one.

Environmental Impact of Sheet Piling

Sheet Piling Retaining Walls are great for stopping erosion and keeping soil in place. Steel Sheet Piles are good for the environment too. They can be used many times, which means less waste.

Steel Sheet Piles can also be recycled completely. This helps save energy and resources needed to make new steel. Using recycled Steel Sheet Piles helps reduce carbon emissions and supports a greener future.

Steel Sheet Piles have many benefits. They don’t harm the environment much. They can be recycled and reused many times.

They last a long time, so you don’t need to replace them often. They also resist corrosion and erosion well. They meet green building standards, like LEED.

Sheet Piling Retaining Walls, made with Steel Sheet Piles, are good for the planet. They help control erosion and stabilize soil. By choosing them, builders can help the environment and give their clients a strong solution.

Choosing the Right Contractor

Choosing the right contractor for sheet piling projects is very important. A good contractor knows about Retaining Wall Systems and Sheet Pile Design. They make sure the project goes well.

Sal Musto has over 20 years of experience. He knows a lot about landscaping and hardscaping. He can help design and install sheet piling walls.

When picking a contractor, think about a few things. These include:

- Experience and expertise in Retaining Wall Systems and Sheet Pile Design

- Reputation and reviews from previous clients

- Cost and budget for the project

A good contractor will look at the site and make a plan. They will tell you what sheet piling to use and how to install it. They also know how to keep the wall in good shape.

Choosing the right contractor means your Retaining Wall Systems will be done right. This makes your property safe and strong. With the right help, your sheet piling project will last a long time.

Costs Associated with Sheet Piling Retaining Walls

Understanding costs in Geotechnical Engineering and Retaining Wall Construction is key. The costs include materials, labor, and equipment. Steel sheet piling costs $30 to $60 per foot, based on type and quality.

The cost-effectiveness of sheet piling depends on design moment and section modulus. A section modulus of 30 in3/ft is suggested for steel sheet piling. The right section modulus and design moment help pick the best and cheapest steel piling.

- Material costs: $30 to $60 per linear foot for steel sheet piling

- Labor costs: $10 to $30 per square foot

- Equipment costs: variable, depending on the type and size of the project

Using durable materials like steel sheet piling can save money in the long run. Financing is available for big projects. Considering other materials like vinyl, concrete, or timber might be cheaper for your project.

Regulatory Considerations

Sheet piling projects must follow local building codes and guidelines. Knowing Soil Mechanics helps pick the right earth retention system. These systems stop soil erosion and keep structures stable.

In the United States, rules for sheet piling come from the International Building Code (IBC) and the American Society of Civil Engineers (ASCE). Here are some important rules:

- Permits and approvals: Getting the right permits and approvals is key before starting a project.

- Local building codes and guidelines: Following these rules is vital for safety and structure strength.

It’s important to talk to geotechnical and structural engineers. They make sure the project follows all rules. By knowing Soil Mechanics and Earth Retention Systems, they design good solutions.

Future Trends in Sheet Piling Technology

The construction world is changing fast. Sheet piling retaining walls are getting ready for big updates. New materials, like steel sheet piles that don’t rust, will make these walls last longer.

New ways to put these walls up are coming too. They use the latest tech to work faster and save time. This makes building projects quicker and easier.

Technology is also changing how we design sheet piling. Soon, we’ll use IoT sensors to watch how these walls do in real time. This will help us fix problems before they start and make the walls work better.

Also, we’re looking for ways to build that are kinder to the planet. This means finding materials and methods that are good for the environment. It’s all about making sheet piling retaining walls better for our planet.

The sheet piling market is growing fast. This is because of more money going into building things and the need for ways to stop floods. This means big things for this important technology in keeping our places safe.